Enter your email to get our newsletter on best-in-class RTLS, AoA, and BLE solutions.

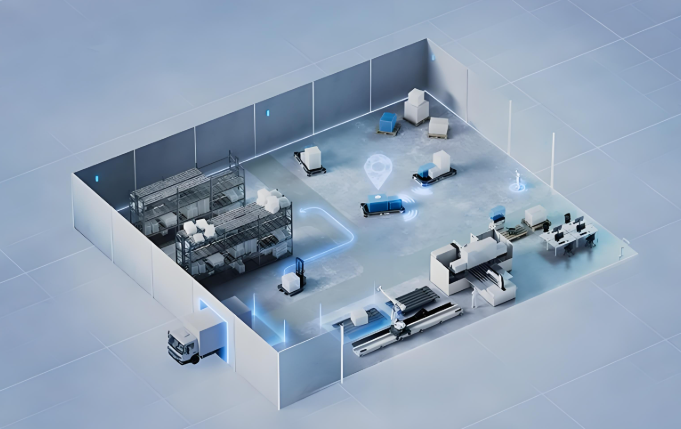

In the process of manufacturing industry moving towards intelligence and flexibility, the real-time positioning system (RTLS) has become a core tool for optimizing production processes and improving resource utilization with its high precision, low latency and multi-mode fusion technical characteristics. By giving "digital identity" to equipment, materials, personnel and work-in-progress (WIP), RTLS builds a space-time perception network covering the entire process, promoting the transformation of manufacturing industry from "experience-driven" to "data-driven".

Flexible production line dynamic scheduling: support multi-variety mixed flow production

In discrete manufacturing fields such as automobiles and electronics, production lines need to frequently switch to produce different models of products. The traditional fixed workstation mode is prone to idle resources and efficiency fluctuations. RTLS realizes "flexible" and "agile" production by tracking the location of materials and tools in real time, and dynamically adjusting the process sequence and equipment parameters in combination with production order requirements.

Two-way data interaction: positioning tags can be integrated with electronic ink screens or LED indicators to automatically display operating instructions according to vehicle models or product models, reducing manual recognition errors;

Intelligent path planning: the system analyzes equipment load and material flow paths, optimizes tool scheduling sequence, and shortens production line changeover time;

Beat balance optimization: by monitoring the dwell time of each process, identifying bottleneck links and dynamically allocating resources, the overall production line efficiency is improved.

Intelligent warehouse transparent management: achieve full life cycle visibility of inventory

Traditional warehouse management relies on manual inventory counting and barcode scanning, and there are problems such as lagging inventory data and misplaced materials. RTLS builds a "digital warehouse map" by binding positioning tags to pallets, shelves and materials, realizing real-time updates of inventory status and intelligent decision-making.

Dynamic inventory monitoring: The system automatically records the time, location and quantity of materials entering and leaving the warehouse, eliminating manual input errors, and improving inventory accuracy to more than 99%;

Intelligent replenishment warning: Based on historical usage data and real-time inventory levels, predict material demand and trigger replenishment work orders to reduce the risk of out-of-stock in line warehouses;

Space utilization optimization: Analyze material storage heat maps, identify inefficient areas and re-plan the layout to improve warehouse area utilization and access efficiency.

Equipment life cycle management: from passive maintenance to predictive operation and maintenance

Equipment failure is the primary factor leading to unplanned downtime, and traditional regular maintenance models are prone to excessive maintenance or missed inspections. RTLS builds a predictive maintenance model by tracking equipment operation trajectories, usage frequency and operating parameters to extend equipment life and reduce operation and maintenance costs.

Load balancing management: Analyze the equipment operation time and the rationality of task allocation, and dynamically adjust the production plan to avoid overload or idleness;

Early warning of faults: Combine sensor data such as vibration and temperature with positioning trajectory to identify abnormal patterns and warn potential faults 72 hours in advance;

Remaining life assessment: Calculate the remaining life of key components based on the frequency of equipment movement and usage intensity, and optimize spare parts procurement and replacement strategies.

Improve both personnel safety and efficiency: Build an intelligent safety protection network

In high-risk industries such as chemical and metallurgical industries, personnel illegally entering dangerous areas or improper operation can easily cause safety accidents. RTLS uses electronic fences and behavior monitoring technology to achieve full-process safety management and control of "pre-prevention-intervention-post-event tracing".

Hazardous area control: Set up virtual fences for areas such as reactors and high-voltage cabinets, trigger sound and light alarms when unauthorized entry and push them to the safety management system;

Emergency rescue acceleration: Automatically locate the injured person and plan the nearest rescue path when an accident occurs, shortening the emergency response time;

Ergonomic optimization: Analyze the movement trajectory and operation time of workers, identify redundant actions and inefficient paths, and optimize the workstation layout to reduce labor intensity.

Quality traceability and process optimization: creating a zero-defect manufacturing system

In the field of precision manufacturing, product quality is affected by multiple factors such as process sequence and residence time. RTLS builds a quality traceability chain and optimizes process parameters by recording the full process position and timestamp of the work-in-progress.

Full process traceability: from the entry of raw materials to the exit of finished products, the positioning data is associated with the production records to achieve rapid positioning of quality problems and responsibility tracing;

Process parameter optimization: Analyze the residence time and movement speed of the work-in-progress in each process, identify bottleneck processes and adjust the production rhythm to improve the line balance rate;

Error-proofing mechanism: Linked with automated equipment, when the material does not enter the designated workstation or the operation sequence is wrong, the operation will automatically stop and alarm.

From production line scheduling to warehouse management, from equipment operation and maintenance to quality control, RTLS is reconstructing the manufacturing value chain through the three-dimensional data of "location + time + identity".